Counseling hotline:

0535-6022126/128/129

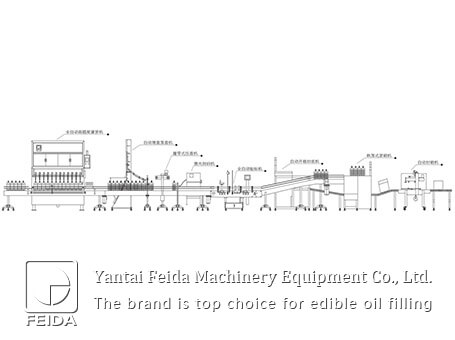

At the beginning of the project, our senior workshop equipment planners, designers, construction team can design the workshop layout according to the customer’s requirements to build a tailored perfect and appropriate workshop.

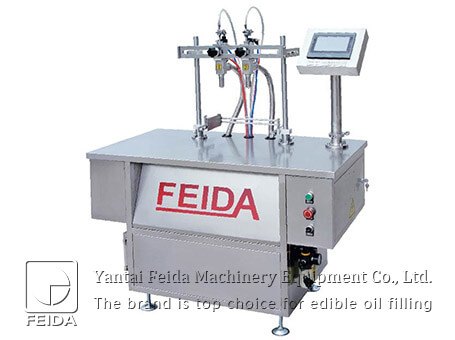

The company has a professional research and development team, regulatory workshops, first-class processing equipment, a post-sales service system covering the whole country and more than 20 years of industry experience.

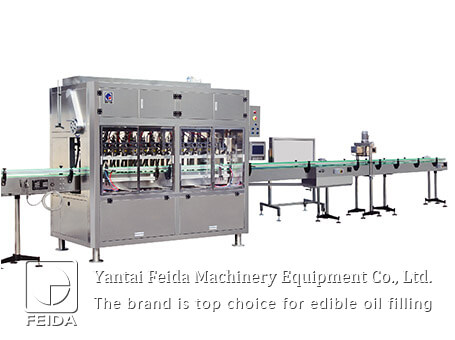

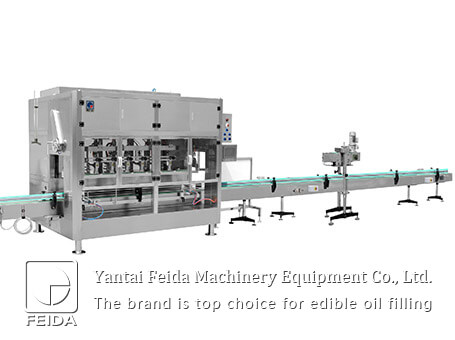

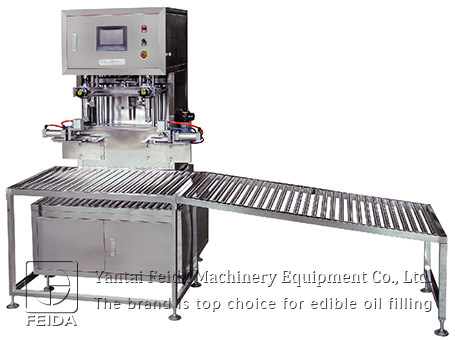

The products cover the whole line from edible oil filling to packing, from conveying to palletizing. The company can also make the line to order so as to meet customers’ various requirements.

The systemic and professional procedure guarantees the close, professional and dedicated post-sales service for the customer’s production line. The company always provides quality products and reliable post-sales service for the customers.

Feida is an experienced enterprise which provides professional solutions on the whole line from edible oil filling to packing, from conveying to palletizing with an employment of qualified professional construction workers. We have established good projects in all industries and we keep pursuing good products with excellent performance and good quality.

Shandong public network security file no.: 37061302000201

Shandong public network security file no.: 37061302000201